Surface-breaking and slightly sub-surface discontinuities (e.g., cracks, incomplete fusion of joints etc.) in ferromagnetic materials can be detected by means of magnetic particle testing. These discontinuities need not be opened to the inspection surface. However, detection sensitivity of this method to such discontinuities decreases rapidly with depth.

Surface-breaking and slightly sub-surface discontinuities (e.g., cracks, incomplete fusion of joints etc.) in ferromagnetic materials can be detected by means of magnetic particle testing. These discontinuities need not be opened to the inspection surface. However, detection sensitivity of this method to such discontinuities decreases rapidly with depth.

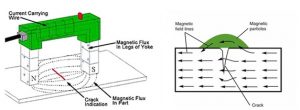

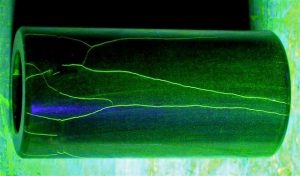

Firstly, ferromagnetic materials are magnetized either locally or overall. Discontinuities in the materials distort magnetic field and cause magnetism to spread out from them; create a magnetic flux leakage field around them. Secondly, the magnetic flux leakage field is revealed by covering the surface with very fine iron particles applied either dry or suspended in a liquid. The particles are drawn and accumulated by the leakage field, providing a visible indication of the discontinuities.

This method is not applicable to non-ferromagnetic materials. Discontinuities that are not at an appropriate angle in the direction of the magnetic field cannot be detected. Very high magnetizing flux may be required for large parts. It is hard to inspect rough surfaces. Paints and coating make the inspection harder. After the inspection, the material should be demagnetized and cleaned.

Application processes respectively, (1) Pre-cleaning, (2) De-magnetisation, if necessary, (3) Application of a background contrast paint if necessary, (4) Magnetization, (5) Application of magnetic particle powders or inks, (6) Interrupting the magnetizing current, (7) Inspection of surfaces for indications of flaws, (8) Evaluation and reporting, (9) De-magnetisation, or re-magnetisation by another method if necessary, and (10) Cleaning and protecting.

Standards:

- EN ISO 9934-X: Non-destructive testing – Magnetic particle testing.

- EN ISO 3059: Non-destructive testing – Penetrant testing and magnetic particle testing – Viewing conditions.

- TS EN ISO 12707: Non-destructive testing – Magnetic particle testing -Vocabulary.

- EN ISO 17638: Non-destructive testing of welds – Magnetic particle testing.

- EN ISO 23278: Non-destructive testing of welds – Magnetic particle testing – Acceptance levels.

- EN 1369: Founding – Magnetic particle testing.

- EN 10228-1: Non-destructive testing of steel forgings – Part 1: Magnetic particle inspection

- EN ISO 10893-5: Non-destructive testing of steel tubes – Part 5: Magnetic particle inspection of seamless and welded ferromagnetic steel tubes for the detection of surface imperfections.