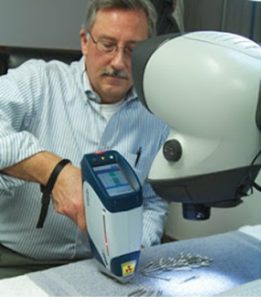

Hand–Held XRF spectroscopy method has been commonly used for Positive Materials Identification / Alloy Verification (PMI/AV), scrap sorting,  Restriction of Hazardous Substances (RoHS/WEEE) etc. Many elements in an atomic number range of 12Mg–92U can be detected non-destructively and quickly in almost all kind of materials (metals, ceramics, polymers, composites etc.) in % or ppm level by means of XRF spectrometer. Fast measurement (2-3 sec) for standard alloys (22Ti–92U), automatically extended times (10-30 sec) for alloys containing light elements (12Mg–22Ti).

Restriction of Hazardous Substances (RoHS/WEEE) etc. Many elements in an atomic number range of 12Mg–92U can be detected non-destructively and quickly in almost all kind of materials (metals, ceramics, polymers, composites etc.) in % or ppm level by means of XRF spectrometer. Fast measurement (2-3 sec) for standard alloys (22Ti–92U), automatically extended times (10-30 sec) for alloys containing light elements (12Mg–22Ti).

Positive Material Identification (PMI), so called Allow Verification (AV), can be described as practical, rapid, non–destructive, reliable, and economic control and verification processes for determination of the chemical composition of materials.

Common PMI/AV spectrometers are X–Ray Fluorescence (XRF) and Arc/Spark–Optical  Emission Spectrometer (OES) because they are portable, practical, rapid and reliable devices.

Emission Spectrometer (OES) because they are portable, practical, rapid and reliable devices.

In order to protect the environment and human health, it is aimed to limit use of hazardous  substances such as mercury, lead, cadmium, chromium VI in electrical and electronic equipment. Within the framework of technical principles, it is ensured that the waste of electrical and electronic goods is recycled in an environmentally friendly manner.

substances such as mercury, lead, cadmium, chromium VI in electrical and electronic equipment. Within the framework of technical principles, it is ensured that the waste of electrical and electronic goods is recycled in an environmentally friendly manner.

In the event that these hazardous substances are below the limit values stated in the Regulation on the Restriction  of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment an published in the Official Gazette dated 30.05.2008 and numbered 26891, the manufacturers may declare RoHS certificate and submit their product to the market. In order to obtain RoHS certificate, firstly, the final product is analyzed in a laboratory. The analyzes are carried out by pre-treating the final product with one of TS EN 62321 standards.

of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment an published in the Official Gazette dated 30.05.2008 and numbered 26891, the manufacturers may declare RoHS certificate and submit their product to the market. In order to obtain RoHS certificate, firstly, the final product is analyzed in a laboratory. The analyzes are carried out by pre-treating the final product with one of TS EN 62321 standards.

For hazardous substances, the limit values are given below:

Mercury – %0,1

Cadmium – %0,01

Lead – %0,1

Chrome VI – %0,1

PBB – %0,1

PBDE – %0,1

Standards:

- TS EN 10315: Routine method for analysis of high alloy steel by X-ray Fluorescence Spectrometry (XRF) by using a nearby technique.

- TS EN ISO 12677: Chemical analysis of refractory products by X-ray fluorescence (XRF) – Fused cast-bead method.

- TS EN 725-4: Advanced technical ceramics – Methods of test for ceramic powders – Part 4: Determination of oxygen content in aluminum nitride by XRF analysis.

- ASTM E322: Standard Test Method for X–Ray Emission Spectrometric Analysis of Low–Alloy Steels and Cast Irons,

- ASTM F2617 – 15 Standard Test Method for Identification and Quantification of Chromium, Bromine, Cadmium, Mercury, and Lead in Polymeric Material Using Energy Dispersive X-ray Spectrometry,

- Pipe Fabrication Institute, PFI ES42: Standard for Positive Material Identification of Piping Components Using Portable X–Ray Emission Type Test Equipment.

Standards:

- TS EN 10204: Metallic products – Types of inspection documents

- TS EN ISO 15156–X: Petroleum and natural gas industries – Materials for use in H2S-containing environments in oil and gas production – Part 1: General principles for selection of cracking-resistant materials

- ASTM A751–07: Standard Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products,

- ASTM E352–18: Standard Test Methods for Chemical Analysis of Tool Steels and Other Similar Medium– and High–Alloy Steels,

- ASTM E353–14: Standard Test Methods for Chemical Analysis of Stainless, Heat–Resisting, Maraging, and Other Similar Chromium–Nickel–Iron Alloys,

- ASTM E354–14: Standard Test Methods for Chemical Analysis of High-Temperature, Electrical, Magnetic, and Other Similar Iron, Nickel, and Cobalt Alloys,

- ASTM E1282–11: Standard Guide for Specifying the Chemical Compositions and Selecting Sampling Practices and Quantitative Analysis Methods for Metals, Ores, and Related Materials,

- ASTM E1476–04: Standard Guide for Metals Identification, Grade Verification, and Sorting,

- ASTM E1916–11: Standard Guide for Identification of Mixed Lots of Metals,

- American Petroleum Institute–Recommended Practice, API–RP 578: Material Verification Program for New and Existing Alloy Piping Systems,

- The Manufacturers Standardization Society, MSS SP-137-2013: Quality Standard for Positive Material Identification of Metal Valves, Flanges, Fittings, and Other Piping Components,

- Process Industry Practices, PIP VESPMI01: Positive Material Identification Specification.

Restriction of Hazardous Substances (RoHS/WEEE) etc. Many elements in an atomic number range of 12Mg–92U can be detected non-destructively and quickly in almost all kind of materials (metals, ceramics, polymers, composites etc.) in % or ppm level by means of XRF spectrometer. Fast measurement (2-3 sec) for standard alloys (22Ti–92U), automatically extended times (10-30 sec) for alloys containing light elements (12Mg–22Ti).

Restriction of Hazardous Substances (RoHS/WEEE) etc. Many elements in an atomic number range of 12Mg–92U can be detected non-destructively and quickly in almost all kind of materials (metals, ceramics, polymers, composites etc.) in % or ppm level by means of XRF spectrometer. Fast measurement (2-3 sec) for standard alloys (22Ti–92U), automatically extended times (10-30 sec) for alloys containing light elements (12Mg–22Ti).

Emission Spectrometer (OES) because they are portable, practical, rapid and reliable devices.

Emission Spectrometer (OES) because they are portable, practical, rapid and reliable devices. substances such as mercury, lead, cadmium, chromium VI in electrical and electronic equipment. Within the framework of technical principles, it is ensured that the waste of electrical and electronic goods is recycled in an environmentally friendly manner.

substances such as mercury, lead, cadmium, chromium VI in electrical and electronic equipment. Within the framework of technical principles, it is ensured that the waste of electrical and electronic goods is recycled in an environmentally friendly manner. of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment an published in the Official Gazette dated 30.05.2008 and numbered 26891, the manufacturers may declare RoHS certificate and submit their product to the market. In order to obtain RoHS certificate, firstly, the final product is analyzed in a laboratory. The analyzes are carried out by pre-treating the final product with one of TS EN 62321 standards.

of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment an published in the Official Gazette dated 30.05.2008 and numbered 26891, the manufacturers may declare RoHS certificate and submit their product to the market. In order to obtain RoHS certificate, firstly, the final product is analyzed in a laboratory. The analyzes are carried out by pre-treating the final product with one of TS EN 62321 standards.