We continue to provide technical support and certification services in all applications with welded manufacturing…

Welder/Welding Operator Performance Qualification, WPQ

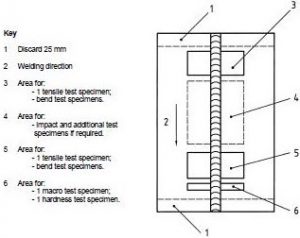

Welder/Welding Operator Performance Qualification Test Report (WPQTR) is a document that shows that a welder or welding operator is capable of welding according to certain standards. The welder / welding operator is tested by applying various destructive and non-destructive examinations / tests on the welded joint produced by the welder / welding operator. Welding tests and inspections/tests are conducted according to a document of Welding Procedure Specification (WPS).

Welder/Welding Operator Performance Qualification Test Report (WPQTR) is a document that shows that a welder or welding operator is capable of welding according to certain standards. The welder / welding operator is tested by applying various destructive and non-destructive examinations / tests on the welded joint produced by the welder / welding operator. Welding tests and inspections/tests are conducted according to a document of Welding Procedure Specification (WPS).

Qualification of welders is applied according to standards “EN ISO 9606–X (2017): Approval testing of welders – Fusion welding”, “EN ISO 14731 (2019): Welding coordination – Tasks and responsibilities”, and “EN ISO 14732 (2014): Welding personnel – Qualification testing of welding operators and weld setters for mechanized and automatic welding of metallic materials”. EN ISO 9606–X (2017) specifies the requirements for qualification testing of welders for fusion welding of steels. It provides a set of technical rules for a systematic qualification test of the welder and enables such qualifications to be uniformly accepted independently of the type of product, location and examiner or examining body. The others identify the essential welding quality related tasks and responsibilities included in welding coordination. The principle of an assessment according to these documents is that welding coordination personnel need to be competent in the welding-related tasks allocated to them. It is presumed that welding coordination personnel have the necessary education, qualifications and experience and are appointed by the manufacturer. Regulatory documents, application standards and contracts can give specific requirements for welding coordination personnel. Otherwise, it is the responsibility of the manufacturer to determine the requirements to be following these documents.

Standards

EN ISO 9606–X (2017): Approval testing of welders – Fusion welding,

EN ISO 14731 (2019): Welding coordination – Tasks and responsibilities,

EN ISO 14732 (2014): Welding personnel – Qualification testing of welding operators and weld setters for mechanized and automatic welding of metallic materials.

Welding Procedure Qualification Report, WPQR

WPQR is a document showing that the welded connection produced is suitable for welding method, material group, additional metal, consumable materials etc. according to the relevant standards, necessary destructive/non-destructive examinations and tests are carried out and the results are in the required competence. It is qualifying and approving a preliminary Welding Procedure Specification (pWPS), becoming WPS. It contains all the data required to qualify a pWPS form.

WPQR is a document showing that the welded connection produced is suitable for welding method, material group, additional metal, consumable materials etc. according to the relevant standards, necessary destructive/non-destructive examinations and tests are carried out and the results are in the required competence. It is qualifying and approving a preliminary Welding Procedure Specification (pWPS), becoming WPS. It contains all the data required to qualify a pWPS form.  Therefore, each WPS document must have a WPQR document that supports it. Briefly, WPS and WPQR are documents that cover all necessary welding parameters, verify and guarantee the welding procedure. For each new welding procedure, a new qualification is required.

Therefore, each WPS document must have a WPQR document that supports it. Briefly, WPS and WPQR are documents that cover all necessary welding parameters, verify and guarantee the welding procedure. For each new welding procedure, a new qualification is required.

As TEKNOLAB®, in our accredited laboratories according to TS EN ISO / IEC 17025 standard, we provide destructive / non-destructive inspection and test services to welder and welding operator certification bodies and welding procedure approval institutions.

Standards

EN ISO 15607 (2019): Specification and qualification of welding procedures for metallic materials – General rules

TSE CEN ISO/TR 15608 (2017): Welding – Guidelines for metallic materials grouping system

EN ISO 15609-X (2019): Specification and qualification of welding procedures for metallic materials – Welding procedure specification

EN ISO 15610 (2005): Specification and qualification of welding procedures for metallic materials – Qualification based on tested welding consumables

EN ISO 15611 (2005): Specification and qualification of welding procedures for metallic materials – Qualification based on previous welding experience

EN ISO 15612 (2018): Specification and qualification of welding procedures for metallic materials – Qualification by adoption of a standard welding procedure

EN ISO 15613 (2005): Specification and qualification of welding procedures for metallic materials – Qualification based on pre-production welding test

EN ISO 15614-X (2017): Specification and qualification of welding procedures for metallic materials – Welding procedure test

EN 10025-1 (2005): Hot rolled products of structural steels

EN ISO 5817 (2014): Welding – Fusion-welded joints in steel, nickel, titanium and their alloys (beam welding excluded) – Quality levels for imperfections

EN ISO 9712 (2014): Non-destructive testing – Qualification and certification of NDT personnel

TSE CEN ISO/TR 25107 (2012): Non-destructive testing – Guidelines for NDT training syllabuses

EN ISO 3834-X (2006): Quality requirements for fusion welding of metallic materials

EN ISO 14555 (2017): Welding – Arc stud welding of metallic materials

EN ISO 15620 (2019): Welding- Friction welding of metallic materials

EN ISO 5178 (2020): Destructive tests on welds in metallic materials – Longitudinal tensile test on weld metal in fusion welded joints

EN ISO 4136 (2013): Destructive tests on welds in metallic materials – Transverse tensile test

EN ISO 5173 (2012): Destructive tests on welds in metallic materials – Bend tests

TS 7226 (1989): Testing of Filler Metals by Means of Weld Metal Specimens-Test Piece for Determining the Hardness for Surfacing

EN ISO 9015-1 (2011): Destructive tests on welds in metallic materials – Hardness testing – Part 1: Hardness test on arc welded joints

EN ISO 9015-2 (2016): Destructive tests on welds in metallic materials – Hardness testing – Part 2: Microhardness testing of welded joints

EN ISO 9016 (2012): Destructive tests on welds in metallic materials – Impact tests – Test specimen location, notch orientation and examination

EN ISO 17639 (2014): Destructive tests on welds in metallic materials – Macroscopic and microscopic examination of welds

ASME IX-BPVC: Boiler and Pressure Vessel Code; Welding, Brazing, and Fusing Qualifications

AWS D1.1–D1.4: Structural Steel