Corrosion tests are quality control tests that are important for determining the economic life and warranty period of the products.

Corrosion tests are quality control tests that are important for determining the economic life and warranty period of the products.

Corrosive effects of aggressive factors such as weather conditions, temperature differences, humidity/fog, marine environment, salt water, pollutant gases on the products are tested. The tests can be conducted in two ways:

Corrosive effects of aggressive factors such as weather conditions, temperature differences, humidity/fog, marine environment, salt water, pollutant gases on the products are tested. The tests can be conducted in two ways:

Real-time retention tests in natural conditions,

Real-time retention tests in natural conditions,- Accelerated laboratory tests where corrosive effects are intensified / increased.

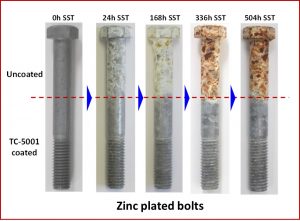

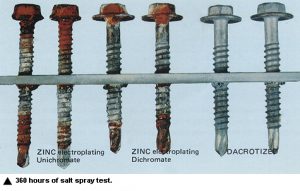

Tests under natural conditions take a long time, and these can be misleading to compare the corrosive effects in different environments. Therefore, accelerated corrosion tests are carried out in a standard corrosion test cabinet where aggressive factors are increased in a controlled manner. In these tests, salty mist spray, continuous condensing adjustable humidity, ventilation, drying / hot air, cooling, sprinkling etc. are applied on the test sample continuously or in a combination alternative cycle. Corrosion performances, service life can be determined, and comparisons can be made by evaluating conditions of bubbling, rusting, cracking, flaking, delamination, corrosion etc. that may occur on the test samples.

Standards:

Standards on accelerated corrosion tests can be divided into four groups: (i) Condensing Moisture Tests, (ii) Salt Spray Tests, (iii) High Moisture Contamination Gas Tests, and (iv) Alternative Cyclic Tests.

1) Condensing Moisture Tests:

EN ISO 6270-1 (2018): Paints and varnishes – Determination of resistance to humidity – Part 1: Condensation (single-sided exposure)

EN ISO 6270-2 (2018): Paints and varnishes – Determination of resistance to humidity – Part 2: Condensation (in-cabinet exposure with heated water reservoir)

EN 3665 (1997): Aerospace series-Test methods for paints and varnishes-Filiform corrosion resistance test on aluminium alloys

2) Salt Spray Tests:

2) Salt Spray Tests:

EN ISO 9227 (2017): Corrosion tests in artificial atmospheres – Salt spray tests

EN ISO 4536 (2000): Metallic and non-organic coatings on metallic substrates-Saline droplets corrosion test (SD test)

EN 2349-402 (2007): Aerospace series – Requirements and test procedures for relays and contactors – Part 402: Corrosion, salt spray

EN 13523-8 (2017): Coil coated metals – Test methods – Part 8: Resistance to salt spray (fog)

EN 13523-8 (2017): Coil coated metals – Test methods – Part 8: Resistance to salt spray (fog)

EN 60068-2-11 (2002): Environmental testing- Part 2: Tests Ka: Salt mist

EN IEC 60068-2-52 (2018): Environmental testing – Part 2: Tests – Test Kb: Salt mist, cyclic (sodium chloride solution)

ISO 9022-4 (2015): Optics and photonics – Environmental test methods – Part 4: Salt mist

3) High Moisture Contamination Gas Tests:

3) High Moisture Contamination Gas Tests:

EN ISO 3231 (1998): Paints and varnishes-Determination of resistance to humid atmospheres containing sülfür dioxide

EN ISO 6988 (2005): Metallic and other non-organic coatings – Sulfur dioxide test with general condensation of moisture

4) Alternative Cyclic Tests:

EN ISO 11130 (2018): Corrosion of metals and alloys – Alternate immersion test in salt solution

EN ISO 11474 (2014): Corrosion of metals and alloys – Corrosion tests in artificial atmosphere – Accelerated outdoor test by intermittent spraying of a salt solution (Scab test)

EN ISO 16151 (2018): Corrosion of metals and alloys – Accelerated cyclic test with exposure to acidified salt spray, dry and wet conditions

EN ISO 16701 (2015): Corrosion of metals and alloys – Corrosion in artificial atmosphere – Accelerated corrosion test involving exposure under controlled conditions of humidity cycling and intermittent spraying of a salt solution

EN ISO 11997-1 (2017): Paints and varnishes – Determination of resistance to cyclic corrosion conditions – Part 1: Wet (salt fog)/dry/humidity

EN ISO 11997-2 (2014): Paints and varnishes – Determination of resistance to cyclic corrosion conditions – Part 2: Wet (salt fog)/dry/humidity/UV light

EN ISO 15710 (2004): Paints and varnishes – Corrosion testing by alternate immersion in and removal from a buffered sodium chloride solution

EN 3212 (2003): Aerospace series – Paints and Varnisher – Corrosion test by alternate immersion in a buffered sodium chloride solution