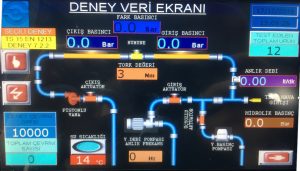

VALVES LEAKAGE TESTING

Mechanical, hydraulic and strength tests of stop valves, ball valves, gate valves are performed precisely in our testing benches developed according to TS 15 EN 1213, TS EN 13828 and TS EN 12288 standards, respectively.

You can watch our “Valve Tester” introduction video from the link below:

https://www.youtube.com/watch?v=AqjJGxlZMA8

Tests Applied to Stop Valves:

According to TS 15 EN 1213 standard, mechanical (bending moment), hydraulic (tightness, pressure resistance, flow capacity) and durability (opening-closing) tests:

In the bending moment test, the bending strength of the stop valve under the applied bending moment is tested. The stop valve must be based on the moment applied without any cracking or breakage. In addition, any deformation should not be affected by the function and tightness of the stop valve.

In the leak proofing test, the tightness of the stop valve is tested at certain static cold-water pressures and times.

In the pressure resistance test, the resistance of the stop valve to cold water hydraulic pressure is tested without permanent deformation, cracking or breaking.

In the opening-closing resistance test, the mechanical strength of the opening-closing mechanism is tested by subjecting the packing group to a certain number of opening and closing operations.

Tests Applied to Ball Valves

According to TS EN 13828 standard, working torque, turning and bending moments, stoppers and shaft-mechanical strengths, hydrostatic sealing, hydrostatic strength, opening-closing strength, angular overlay tests:

According to TS EN 13828 standard, working torque, turning and bending moments, stoppers and shaft-mechanical strengths, hydrostatic sealing, hydrostatic strength, opening-closing strength, angular overlay tests:

In the working torque test, the working torque is measured under a certain static pressure and at a rotational speed of ± 5 cycles / minute.

The torque test is applied in both directions to ball valves with internal threads on both sides. Working torque is measured by internal and external sealing under rated pressure.

In the hydrostatic tightness test, the tightness of the sphere (inner seal) and the assembled ball valve (outer seal) under cold water pressure is tested.

In the hydrostatic resistance test, the resistance of the ball valve to cold water hydrostatic pressure is tested without permanent deformity, rupture or breakage.

In the resistance test, the resistance of the ball valve to a series of operating cycles of jog mechanism is tested.

In the angular overlay test, the valve is opened slowly until flow is visible, and then closed slowly until the flow is interrupted. The angle between the flux and non-flux positions is measured.

STANDARDS

EN 1213: Building valves – Copper alloy stop valves for potable water supply in buildings – Tests and requirements.

EN 13828: Building valves – Manually operated copper alloy and stainless-steel ball valves for potable water supply in buildings -Tests and requirements

EN 12288: Industrial valves – Copper alloy gate valves